JK Paints Pvt. Ltd. has their manufacturing facility set up in the most strategic location of Bangalore,Karnataka.

Manufacturing Facilities

Location

The factory is only 20 KMS from the Bangalore International Airport (BIAL). Its close proximity to the Bangalore-Hyderabad national highway-NH 207 makes it a centre point for 4 southern Indian states. It makes it easier to receive raw materials and send goods out on time. Western India can be connected to very easily.

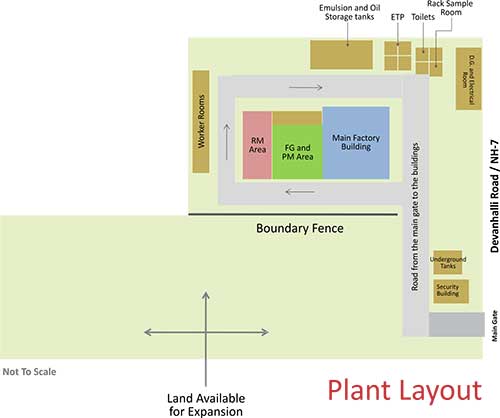

Layout

The unit is spread over an industrial converted land of 6.8 acres and manufactures various types of water based paints, allied products and intermediaries.

Total constructed area on the premises is 40000 square feet.This comprises of the following :

- Production Building

- Separate Raw Material Storage area

- Separate packing material storage area

- Separate Finished Goods Storage area

- Modern administrative office

- Most recent Quality assurance laboratory

- Rack sample room

- Security building

- Electrical and DG Room

- Effluent treatment plant ETP

- Living/Lodging facilities for the workers on campus3

- With the aim of protecting, nurturing and saving our mother earth we have planted and grown number of trees and plants. There is a defined green belt area.

Production Capabilities

Plant Capacity : JK paints has a wide variety of machines that can make both stiff and liquid paints. The current machinery is capable of producing 6000 Metric Tons of stiff paints per month and 3000 Kilo Litres of liquid paint per month. Thus totalling to 9000 Metric Tons of paint per month. Annually this sums upto about 1,08,000 Metric tons of production capacity.

| Stiff Paints | Liquid Paints | Powder Putty | Total | |

| Monthly Capacity | 3,000 MT | 3,000 KL | 3,000 MT | 9,000 MT/KL |

| Annual Capacity | 36,000 MT | 36,000 KL | 36,000 MT | 1,08,000 MT/KL |

Machineries

We have the following kinds of machinery installed in our manufacturing set up. These machines are fabricated specially to ensure finest quality of production and 100% safety of workers. Our machines go under regular maintenance program to prevent any damage and loss of production.

| SR No. | DESCRIPTION |

| 1 | Pug Mills |

| 2 | High speed dispersers with variable drive |

| 3 | Twin sharp disperser with dual drive |

| 4 | Thinning tanks |

| 5 | Caesin Reactors |

| 6 | Stainless steel Vortexes |

Quality Assurance Laboratory and Testing Facilities

JK Paints has set up one of the finest laboratories with the latest testing equipment to ensure best quality material to our customers. Spread over an area of 1000 square feet, it is supported by a Rack sample storage room. We at JK Paints ensure that each and every batch of every product and intermediary goes thorough testing. Our incoming raw materials and packing materials are also tested here. Our people in the laboratory have detailed understanding about the product and go through regular trainings to upgrade their knowledge and testing skills.

The following are the various kinds of equipments in the laboratory.

| DESCRIPTION | DESCRIPTION |

| COLOUR COMPUTER & MATCHING CABINET | MUFFLE FURNACE |

| BROOKE FIELD VISCOMETER | PENETROMETER |

| BURST STRENGTH TESTER | REFLECTANCE METER |

| GLOSSOMETER (SHEEN) | SCRATCH HARDNESS TESTER |

| HAND PULL STRENGTH TESTER | SPECTROPHOTOMETER |

| SHEEN HEGGMEN GUAGE ( 0 TO 8) | STORMER VISCOMETER (SHEEN) |

| FORD CUP | STOP WATCH |

| BAR COAT APPLICATOR(150 MICRON) | VARIOUS SEIVES |

| BAR COAT APPLICATOR(500 MICRON) | THERMOMETER (MERCURY) |

| DESCICATOR | WATER BATH |

| DIGITAL PH METER | VACUUM PUMP |

| HOT AIR OVENS | W.P.L CUP ( 100 CC ) |

| MINI H.S.D | IR CHAMBER |

Environmental Protection

JK paints believe they have a social responsibility towards maintaining a clean and green environment. We conduct grow more trees drive once a year where all our employees help in to add on more plants and trees in the premises. Production and other wastes generated undergo correct treatment procedure in the ETP( Efffluent Treatment Plant). Rain water harvesting and drip irrigation methods are used to conserve and preserve water.